Choosing the Right Concrete Scanning Tools

Elevate Your Building Process With the Strategic Insights of Concrete Scanning for Boosted Productivity

In the world of modern building methods, the mission for efficiency and accuracy is paramount. Embracing ingenious modern technologies has actually ended up being a keystone for accomplishing these purposes. One such modern technology that has transformed the construction sector is concrete scanning. By harnessing the tactical insights given by concrete scanning, building and construction professionals can open a world of enhanced productivity and structured processes. The ramifications of integrating concrete scanning go far beyond surface-level benefits, offering a profound influence on job results.

Benefits of Concrete Scanning

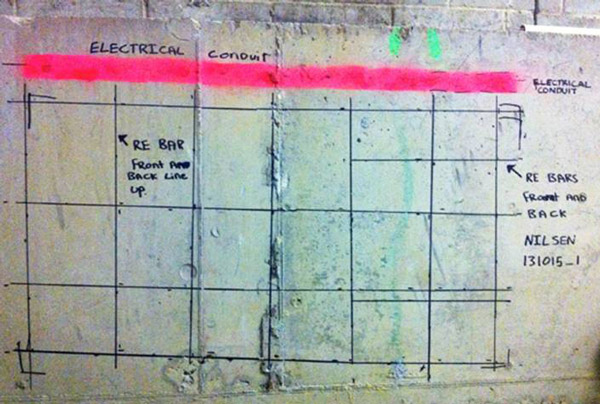

Enhancing task efficiency and security, concrete scanning supplies a non-destructive technique for finding hidden things within concrete structures. By utilizing innovations such as ground-penetrating radar (GPR) and concrete x-ray imaging, building and construction teams can accurately situate rebar, post-tension wires, electric conduits, and various other obstructions prior to boring, cutting, or coring into concrete.

The advantages of concrete scanning are many. It decreases the risk of unintended damage to essential structural elements, reducing the likelihood of costly fixings and job delays. It boosts worker security by supplying real-time insights right into the area of covert dangers - Concrete Scanning. Building websites can be complex atmospheres, and recognizing what exists beneath the surface area can prevent mishaps and injuries.

In addition, concrete scanning promotes overall job performance by improving operations and stopping rework. By determining possible issues beforehand, teams can adjust their plans proactively, saving time and resources in the future. Basically, the fostering of concrete scanning innovations is a tactical investment that pays returns in terms of efficiency, cost-effectiveness, and security.

Modern Technology Integration for Efficiency

Concrete scanning's ability to streamline operations and improve task performance can be further maximized via critical assimilation of innovative modern technologies. By including Building Info Modeling (BIM) software application right into concrete scanning procedures, construction teams can attain a greater degree of accuracy and control. BIM enables for the creation of 3D models that supply in-depth insights right into the job, allowing better decision-making and reducing the possibility of errors. Furthermore, the combination of Augmented Reality (AR) modern technology with concrete scanning can improve on-site visualization, allowing task supervisors and employees to overlay digital information onto the physical atmosphere in real time. This can help with a lot more precise positioning of elements and improve interaction among employee. The usage of drones for airborne surveys in combination with concrete scanning can quicken information collection and evaluation, making it possible for faster decision-making and progress monitoring. On the whole, the critical integration of these technologies can significantly boost effectiveness and performance in building navigate here and construction projects.

Preventing Pricey Errors

How can meticulous focus to detail during concrete scanning processes assist building groups in avoiding expensive errors? By using advanced scanning innovations such as Ground Passing Through Radar (GPR) and electromagnetic induction, building and construction groups can precisely spot rebar, energies, voids, and various other obstructions within concrete frameworks. Additionally, concrete scanning assists in ensuring structural honesty by determining weaknesses or problems in the concrete very early on, allowing for timely repairs and alterations.

Enhancing Project Administration

Careful focus to information during concrete scanning refines not just aids in avoiding expensive errors however additionally lays a solid structure for effective task management in building ventures. By incorporating concrete scanning innovation right into job management methods, construction teams can streamline workflows, improve interaction, and guarantee that jobs remain on track.

Concrete scanning gives valuable insights into the structural stability of existing aspects, permitting task supervisors to make enlightened choices regarding design modifications or building series. This aggressive method lessens the threat of unexpected delays or remodel, inevitably conserving time and resources. In addition, the information gotten from concrete scanning can be integrated right into Structure Info Modeling (BIM) systems, making it possible for real-time collaboration and control amongst different stakeholders.

Additionally, concrete scanning assists job managers determine prospective dangers or challenges before they escalate into larger issues, promoting a more secure workplace for all entailed. With boosted exposure and accuracy provided by concrete scanning technology, task managers can efficiently plan, keep an eye on, and perform building projects with better effectiveness and self-confidence.

Optimizing Productivity

One key aspect of maximizing productivity is through the fostering of concrete scanning technology. By using ground-penetrating radar (GPR) and various other scanning methods, construction teams can precisely situate rebar, conduits, and other subsurface components, reducing the danger of pricey errors and delays during excavation and exploration.

Furthermore, accepting Structure Information Modeling (BIM) software can considerably improve performance by creating comprehensive 3D versions that boost project visualization and control among different trades. BIM permits better clash detection, allowing problems to be recognized and solved prior to construction also begins, saving time and resources in the future.

Applying a lean construction technique, which focuses on removing waste and enhancing effectiveness throughout all project Resources stages, is one more efficient strategy for taking full advantage of performance. By fostering partnership, interaction, and continuous enhancement, building teams can function extra cohesively towards accomplishing job goals in a structured and effective fashion.

Final Thought

To conclude, the strategic implementation of concrete scanning in the building and construction process provides many benefits, including raised effectiveness, cost use this link financial savings, improved task monitoring, and improved performance. By incorporating this innovation, construction groups can prevent costly mistakes, improve their operations, and maximize their total task output. Concrete scanning is an important tool that can boost the building and construction procedure and lead to more lucrative and successful outcomes.